The Strategic Role of Early Dimensioning

In the world of car development, early dimensioning plays a pivotal role. It ensures that the designs and creation processes are both efficient and cost-effective. By integrating strategic pre-dimensioning at the onset of development, companies can significantly reduce the need for costly modifications later in the process. The principle is simple. “The soonest we invest, the lowest we invest.”, says Pascal Pancrace, Head of Simulation Innovation Projects at Renault.

How Early Dimensioning Helps Analyze Structure and Cut Development Costs in Automotive Design

• Cost Efficiency: Early dimensioning is inherently more affordable than making changes later in the development cycle. As Mr PANCRACE puts it, “Late modification is always very, very expensive.”

• Error Prevention: By identifying potential design issues early, manufacturers can avoid venturing down unfeasible paths, ensuring that resources are not wasted.

• Streamlined Processes: With early dimensioning, the design process can be aligned with initial styling choices, reducing the need for extensive redesigns and ensuring smoother transitions from concept to reality.

“Early dimensioning is strongly cheap. It helps in identifying what is impossible very soon.”

Concept Structure Engineering: A Structural Engineering Software Game Changer in Early Dimensioning

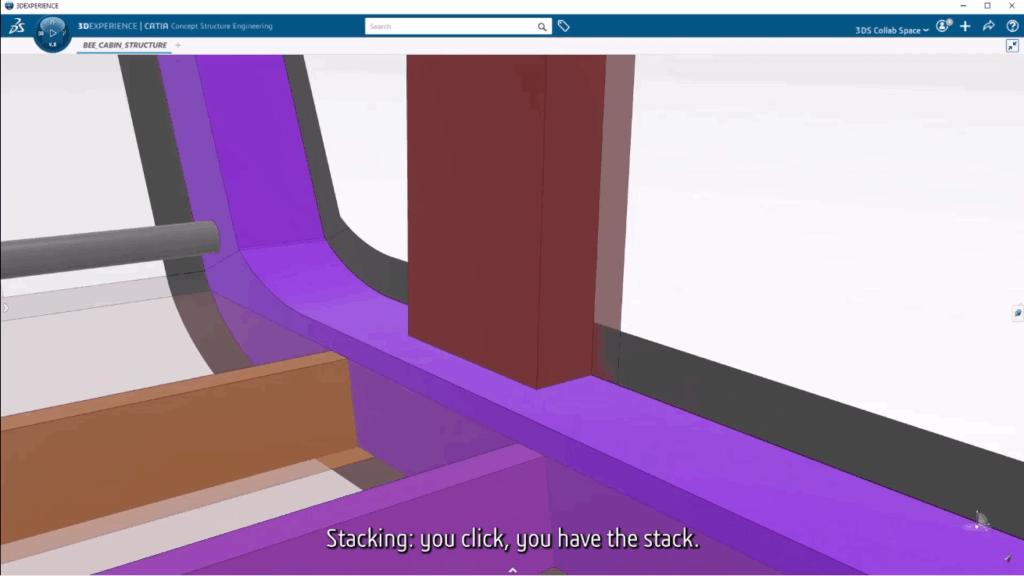

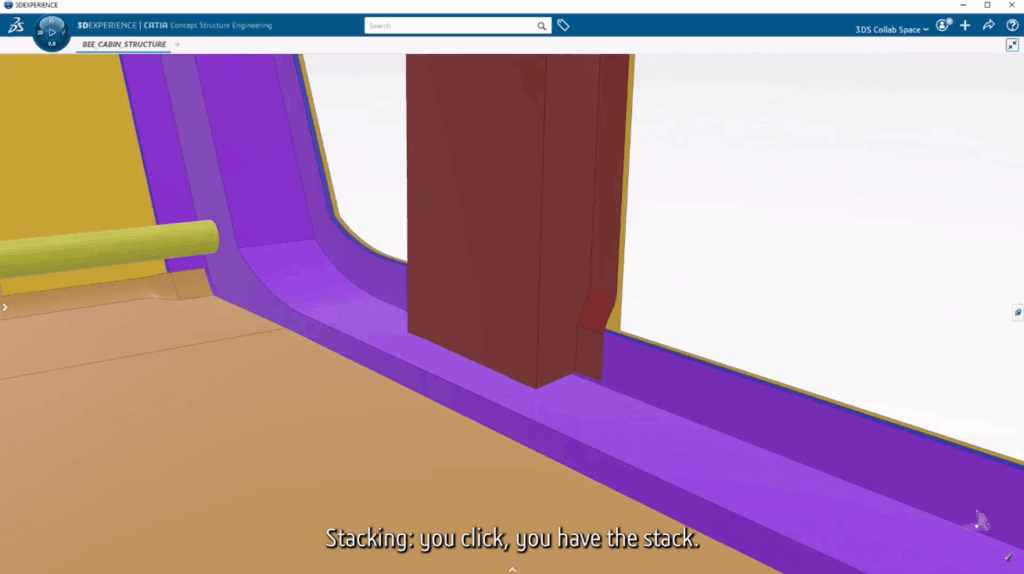

Concept Structure Engineering (CSE) offers solutions that enhance the pre-dimensioning process, providing solutions that enable designers to anticipate future challenges effectively. With innovations like the stacking feature and mapping technology, CSE allows for seamless part integration in a single layer geometry, adapting to complex surfaces with ease.

Key Innovations in CSE

• Stacking Features: This feature simplifies the generation of multi-layer results by automating stacking from a single layer and an offset.

• Adaptive Design: The ability to create parts that automatically adapt with existing structures and adjust to the curvature of other components. This enhances design flexibility and reduces manual adjustments.

“You click, you have the stack. Just extraordinary.”

Benefits of Early Digital Dimensioning

• Time Savings: By incorporating dimensioning into the digital development phase, car manufacturers can ensure that the design aligns with architectural and stylistic choices from the start.

• Enhanced Creativity: Reducing the time spent on iterative redesigns allows teams to focus on innovation and creativity. With less time dedicated to resolving design conflicts, more energy can be directed towards innovative design solutions, enhancing overall productivity.

“With CSE, you don’t spend any more time to express your idea. You get your idea just in a few seconds.”

The Future with Human-Machine Interfaces

As technology evolves, the integration of advanced Human-Machine Interfaces (HMI) is becoming increasingly crucial.

The Role of HMI in Car Development

• Improved Communication: A robust HMI ensures that critical data is effectively communicated to vehicle project teams. This enhances decision-making and increases adoption rates.

• Higher Adoption Rates: With a solid mathematical engine, new solutions can achieve adoption rates of up to 70-80%.

“With a good HMI based on strong solvers, we can have up to 70, 80% of adoption.”

Conclusion

Incorporating early dimensioning into the car development process is not just a strategic move; it’s a necessity in today’s fast-paced automotive industry. By leveraging advanced solutions like Concept Structure Engineering. They can also reduce costs and foster innovation. As the industry continues to evolve, those who adopt these practices early will undoubtedly reap the most benefits. This paves the way for more sustainable and innovative car designs.

FAQ

What is the structural engineering definition?

Structural engineering is a specialized branch of engineering focused on the design and analysis of structures that support or resist loads. It encompasses a wide range of applications, including automotive, railway, other mobility sectors, and even aerospace structure types. The goal is to create safe and efficient structural frameworks that withstand environmental forces and ensure stability.

Why choose structural engineering?

Choosing structural engineering means working at the core of product development, where innovative structural designs are crucial for safety and sustainability. This field allows engineers to impact everyday humans by ensuring the integrity of everything from buildings to transportation systems.

What is structural engineering design?

Structural engineering design involves creating detailed plans for structures that consider material properties, load conditions, and environmental factors. It combines rigorous analysis with practical considerations to develop efficient structural frameworks. Whether designing cars, trains, or aerospace components, engineers must ensure that the structures meet safety standards while optimizing performance.

How does early dimensioning with Concept Structure Engineering improve the car design process?

Early dimensioning using Concept Structure Engineering (CSE) streamlines the car design process. It allows designers to anticipate and solve structural challenges from the start. Features like stacking technology and adaptive design help parts integrate smoothly with complex surfaces, reducing costly redesigns and saving time. This means manufacturers can focus more on creativity and innovation while ensuring the final design is both efficient and structurally sound.