QIDI Max4: A New Standard for Large Enclosed Desktop Printers

The heated bed is also very well made. It uses a full silicone layer with many heating wires placed close together. This helps the bed heat evenly from edge to edge. Strong insulation under the bed keeps the temperature steady. This gives better first-layer grip and helps stop warping on large prints.

The Max4 also comes with a high-flow hotend that can push forty cubic millimeters of material per second. This lets you print faster while still keeping good detail. The hardened steel nozzle can handle common filaments like PLA and ABS, as well as tougher options such as carbon fiber nylon.

QIDI also introduces its new Active Toolhead Cooling System, called the Polar Cooler. It sends cool air directly to the extruder and the filament path. This helps prevent clogs and keeps temperatures under control. Along with it, the second-generation Active Chamber Heating system keeps the chamber warm up to 65°C. This makes printing high-temperature materials like ABS, ABS-CF, and PC much easier and more stable.

QIDI Max4: Stability and Precision Taken Further

To deliver cleaner surfaces and fewer artifacts, the Max4 uses a closed-loop motor system on the XY axis. This major upgrade brings three key advantages:

- Greater

Stability: The system prevents step loss by monitoring encoder errors in a closed loop and instantly compensating for deviations, thereby

significantly reducing layer misalignment.

- Improved accuracy: Reduced torque ripple results in smoother motion and fewer visible surface imperfections.

- Higher efficiency: The motors run cooler and quieter, improving longevity and reliability.

The Z axis also sees a significant refinement with 2 mm lead screws and an anti-backlash nut. Together, they eliminate vertical play, improve Z-axis accuracy, and produce cleaner surfaces on tall prints.

Additional pro-grade features include an updated auto-leveling system, industrial linear rails, and custom 1.5GT belts. All combined, they form a solid motion platform built for long-term precision.

QIDI Max4: Smarter Design, Easier Workflow

A fast processor powers the Max4’s new AI system. With its built-in HD camera, the printer watches the print in real time. It looks for common problems like spaghetti or broken supports. If it finds something wrong, it pauses the print and sends an alert. This helps save time and material.

The new interface is easier to use, and the larger screen makes the controls feel smoother. The Max4 also works with the QIDI BOX, which adds multi-color and multi-material printing. It can use up to sixteen colors and can dry filament at up to 65°C.

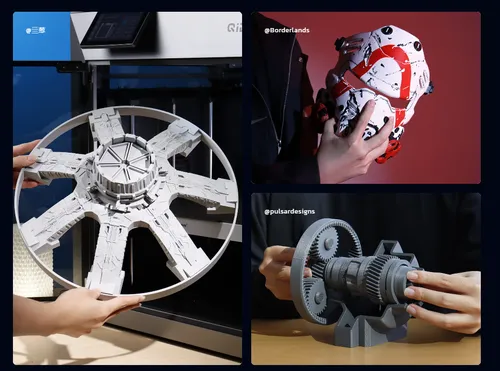

Thanks to its strong heat control, solid hardware, and wide material support, the Max4 can handle many types of projects. It works well for engineering parts, detailed prototypes, or colorful artistic models.

Quick Specs Summary

- Build volume: 390 × 390 × 340 mm

- Heated bed: Full-surface silicone thermal layer with uniform heating and insulation

- Hotend flow rate: 40 mm³/s

- Nozzle: Hardened steel, supports PLA, ABS, CF-reinforced materials

- Chamber heating: Up to 65°C

- Cooling system: Polar Cooler active toolhead cooling

- Motion: Closed-loop XY motors, 2 mm lead screws on Z, anti-backlash nut

- Additional hardware: Auto-leveling sensor, industrial linear rails, 1.5GT belts

- AI features: Real-time print monitoring with an HD camera and automatic pause

- Multi-material: QIDI BOX support for up to 16 colors with 65°C filament drying