Yes, Europe is finally sending its first rover to Mars — and it could help answer one of science’s biggest questions: has life ever existed there? The mission is called ExoMars, and at its core is the Rosalind Franklin rover — a sophisticated mobile lab designed to dig two metres beneath the Martian surface in search of ancient signs of life.

Though it’s a European Space Agency (ESA) mission, the UK is playing a leading role. Britain has contributed around €287 million to the project — second only to Italy — and is responsible for building the rover in-house, along with several key scientific instruments and landing systems.

To get an inside scoop, we talked with two UK experts: Caroline Rodier, project manager for the Rosalind Franklin Mission Landing Platform at Airbus Defence and Space UK, and Dr. Nick Waltham, Technology Research and Innovation Team Lead at STFC’s RAL Space.

Why is this Europe’s boldest Mars mission yet? You’re about to find out.

Built, Delayed, Reborn: Why Does ExoMars Rover Take 20 Years to Launch?

The ExoMars program was never meant to be a single-shot mission. From the beginning, ESA envisioned a two-part approach to maximise the chances of detecting signs of life on Mars. The first phase launched in 2016 — the Trace Gas Orbiter (TGO), still operational today, which maps atmospheric gases like methane that could hint at biological activity. But the second phase, the real showstopper, is the Rosalind Franklin rover: Europe’s first attempt to land and operate a rover on another planet. Its goal is bold — to drill 2 metres below the Martian surface to search for ancient biomarkers protected from radiation and oxidation.

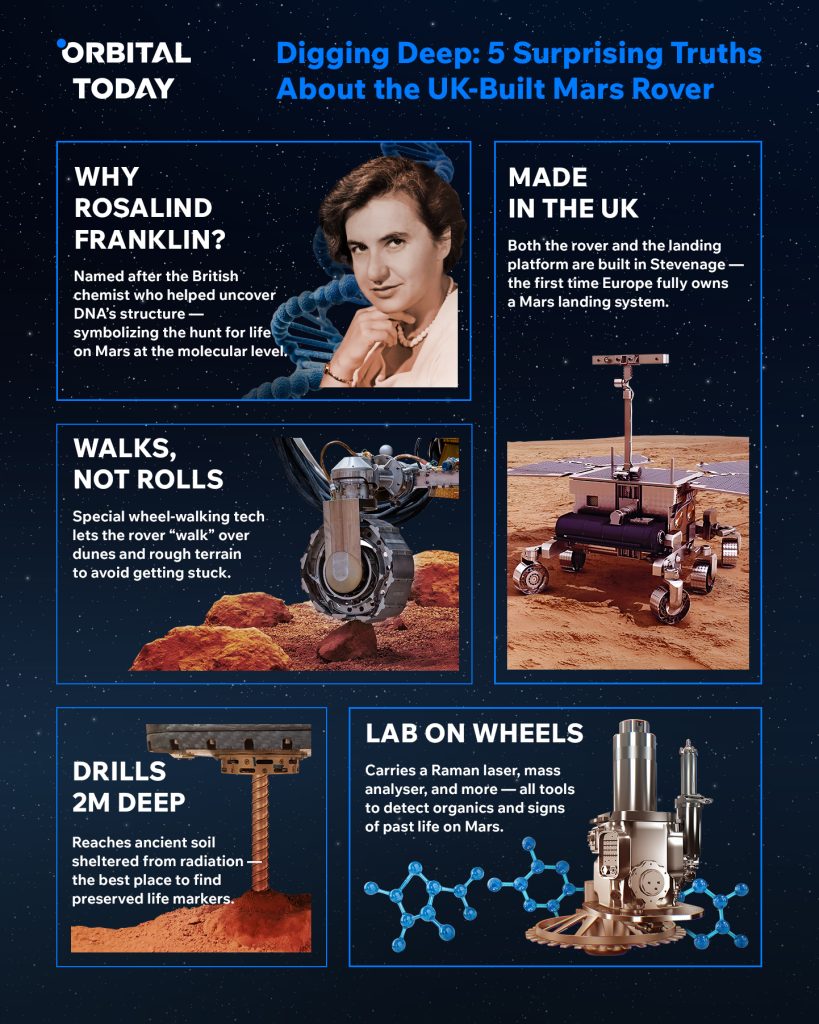

Why Rosalind Franklin?

Built in the UK and powered by a European landing platform, the rover is named in honour of Rosalind Franklin, the British chemist whose uncredited X-ray work revealed the structure of life’s genetic code and contributed to the discovery of DNA’s double helix. She tragically died young in 1958. It was a name chosen to reflect not only scientific brilliance but perseverance — a fitting symbol for a mission about to face its toughest challenge.

Against All Odds

Managing Director of Airbus Defence and Space UK Kata Escott said, “Delivering the Rosalind Franklin rover to the surface of Mars is a huge international challenge and the culmination of more than 20 years of work.” But why so long?

In the early 2000s, ESA launched the ExoMars mission. The concept took shape in 2004, and by 2005, ESA had formalised a partnership with Russia’s Roscosmos to bring the mission to life. Originally slated for launch in 2011, the mission faced a series of delays. By 2018, the rover was ready in design, but technical issues — including payload integration and delivery timing — pushed the launch to 2020. In 2019, Airbus completed construction of the rover in a specially built cleanroom in Stevenage, designed to meet strict bioburden protocols, and prepared it for handover to the mission’s prime contractor, Thales Alenia Space.

What were the main challenges Airbus teams in Stevenage faced while developing the rover?

Building a rover for Mars is never simple — but for the Airbus team in Stevenage, one challenge stood above the rest: keeping it perfectly clean.

We asked Caroline Rodier, Rosalind Franklin Landing Platform Project Manager at Airbus Defence and Space UK, to share the toughest parts of the journey. Her answer? Planetary protection.

“The rover had to be built in a very sterile environment – to ensure that no traces of life are taken to Mars,” she explained. “A special bio-burden cleanroom was built, which was then cleaned and sterilised over a 6-month period to verify that no microbes/bacteria were present. Strict protocols on working in the space were devised, special clothing used where only the eyes of the operatives were exposed, and even then eye protection glasses had to be worn to prevent eyelashes falling onto the rover hardware during assembly.”

But that wasn’t the end of the roadblocks. Parachute problems in 2020 forced another delay. Then, in 2022, everything came to a standstill. Russia’s invasion of Ukraine led ESA to suspend cooperation with Roscosmos, cutting off access to both launch services and critical components for the landing platform.

The ExoMars mission refused to fade. In 2024, with fresh support from the UK and Italian Space Agencies and a new partnership with NASA, ESA rebooted the project with a new target: launch in 2028, original science goals for the rover intact. Rosalind Franklin is now one of Europe’s most ambitious space collaborations, led by Thales Alenia Space (Italy) with the rover built by Airbus Defence and Space (UK). Germany’s OHB provides the carrier module, Leonardo supplies the drill, and a French-led team develops the parachutes — with over 60 companies involved across Europe. Italy is the top funder, but the UK follows closely, investing nearly €287 million.

UK universities also play a vital role in the mission’s scientific goals. As Dr. Nick Waltham, Technology Research and Innovation Team Lead at RAL Space, explains:

“UK universities, RAL Space in collaboration with European universities, institutes and industry have worked together to develop the rover’s extensive suite of instrumentation. Each instrument has a Principal Investigator (PI) that leads their instruments consortium. Once completed, the instruments will be integrated onto the rover through ESA’s Prime.”

Replacing Russian Tech: British Innovation Steps Up

When geopolitical fractures grounded ESA’s partnership with Russia in 2022, the future of Europe’s most ambitious planetary mission hung in the balance. Critical components, from instruments to infrastructure, needed new homes – fast. In a remarkable display of resilience and ingenuity, UK scientists and engineers stepped up.

Among the most significant UK-led breakthroughs are the development of a new landing platform and Enfys, a high-resolution infrared spectrometer that replaces Russian hardware.

“The Landing Platform, originally done by Russia, is now developed in the UK,” explained Caroline Rodier, Landing Platform Project Manager at Airbus Defence and Space. “The associated key technologies that we are developing here in the UK are the propulsion system, the structure, and the thermal control system to keep the lander within the right range of temperature from launch, cruise and the few days on surface. Additionally, we are leading the development of the mechanisms (landing legs, egress ramps) that are fitted on the lander, with our own industrial consortium.”

In March 2024, Airbus UK secured a £150 million contract from Thales Alenia Space, the mission’s prime contractor, to completely rebuild the rover’s landing platform — a role once held by Russia.

Meanwhile, UK researchers have also stepped in to fill a key scientific gap left by the suspended ISEM instrument. As Dr. Nick Waltham explained:

“Enfys simply means ‘rainbow’ in Welsh. In 2023, the UKSA invited a consortium of Aberystwyth University (PI: Dr Matt Gunn), UCL/MSSL and RAL Space to develop a new IR spectrometer, Enfys, to replace the Russian ISEM instrument on the ESA ExoMars rover. It will provide essential complementary science to the rover’s PanCam visible-light imager provided by UCL/MSSL (PI: Prof Andrew Coates). Together they will search for biomarkers of extant life.”

Working alongside PanCam, the panoramic imaging system, Enfys will analyse the Martian surface and subsurface in infrared light — offering scientists a powerful new tool for identifying signs of life. Together, they form a high-resolution scientific pair that brings Europe one step closer to unlocking Mars’ biological secrets — without relying on Russian technology.

This Is How Rosalind Franklin Will Hunt for Life Where No Rover Has Looked

The Rosalind Franklin rover brings powerful new capabilities to the Red Planet — ones that could finally unlock the secrets of life on Mars.

Dr. Nick Waltham highlights one of its most groundbreaking features – a new capability to gather samples from below the Martian surface.

“It will collect samples with a drill down to a depth of 2 m and analyse them with the rover’s analytical instruments in an onboard laboratory. Underground samples are more likely to include biomarkers, since the tenuous Martian atmosphere offers little protection from radiation and photochemistry at the surface.”

This deep drilling ability is crucial because the surface of Mars is constantly bombarded by radiation and charged particles, given the planet’s lack of a global magnetic field. As Caroline Rodier explains:

“On Earth the magnetosphere protects the Earth’s surface from incoming radiation and charged particles creating Auroras when they collide with the Earth’s upper atmosphere. If life exists, or existed on Mars, it is unlikely to have survived on the irradiated surface. Rosalind Franklin will drill down two metres – it is thought about 50cm of Mars regolith (Mars’ soil/dust etc) is enough to stop radiation penetrating further into the surface. The rover’s radar will search for bedrock 2 metres below the surface, then it will drill down to recover a sample from directly above the bedrock – which may also contain water and therefore more favourable conditions for life.”

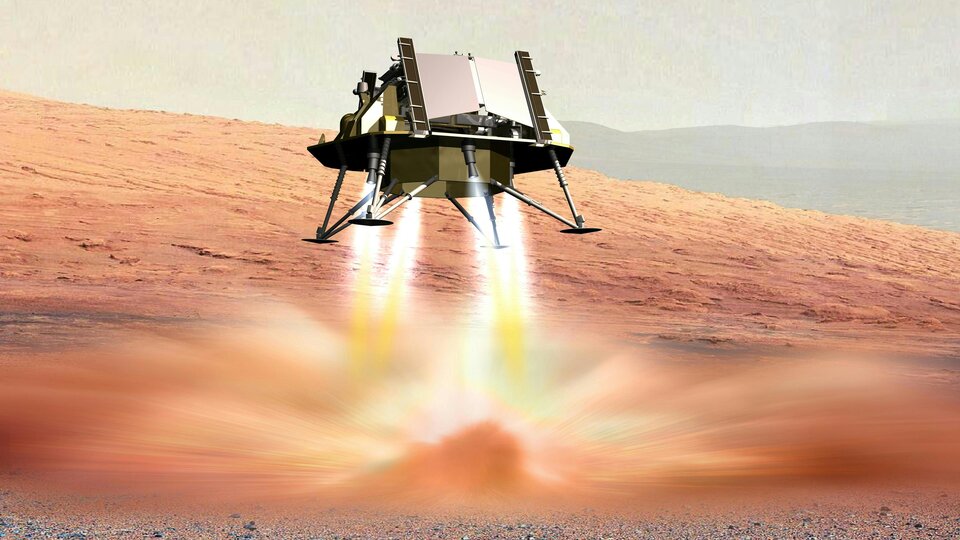

Ensuring a safe touchdown on Mars is another critical challenge. Caroline describes the innovative features of the landing platform Airbus is developing: “The landing platform will have its own rocket engines to ensure a smooth safe landing onto the planet’s surface – the engines come from NASA and are the same kind as the ones used to deliver NASA’s rover landing Perseverance in 2021 onto the Red Planet”.

It also includes two ramps – one at each end. This is in case one side is blocked by boulders and prevents the ramp deploying correctly. The rover can do a U-turn on the platform to ensure it will drive forwards down the ramp after landing. The landing legs, four in total, “provide energy absorption to attenuate touch-down loads of the lander payloads/equipment to their existing qualification levels. This is particularly critical for the Rover.”

Mars’ harsh environment poses further challenges, especially freezing nights that can drop to -130°C. To survive this, Rosalind Franklin is thermally insulated and “will also be equipped with Radioisotope Heater Units to keep the rover warm,” Caroline adds.

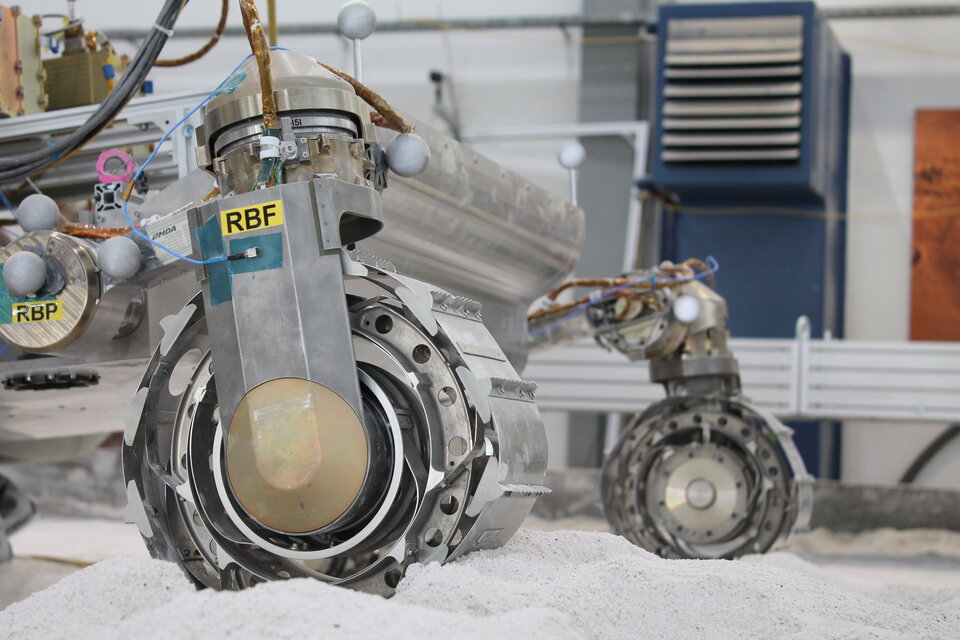

Testing has been equally rigorous. Airbus built a Mars yard test facility to develop and validate the rover’s autonomous navigation capabilities. Since signals between Earth and Mars can take up to 45 minutes one way, remote control is impractical.

Caroline explains, “Airbus developed autonomous navigation for the rover so that it will be able to navigate safely across the surface of Mars without intervention from Earth. It is designed to be able to travel up to 100 metres a day.”

Together, these features and technologies make Rosalind Franklin not just a rover, but a highly advanced mobile laboratory, designed to dig deeper and explore Mars more thoroughly than ever before.

Mars 2030

Peter Kyle, the UK Technology Minister, put it well: “This inspiring example of world-class British science will bring us one step closer to answering long-asked questions about potential life on Mars. By landing the first ever home-grown rover on Mars, Airbus will not only help Britain make history and lead the European space race, but will also create hundreds of highly skilled jobs and inspire the next generation of scientists and engineers.”

The Rosalind Franklin rover is on track to launch from Florida’s Kennedy Space Center between October and December 2028. If all goes well, it will arrive on Mars in 2030, ready to dig deep and unlock mysteries that could rewrite what we know about life beyond Earth — a moment of pride and possibility for the UK and all of Europe.

We’re grateful to Caroline Rodier and Dr. Nick Waltham for taking the time to share their expertise and behind-the-scenes perspective with Orbital Today!