As your ecommerce business scales, the manual processes that supported your initial growth become a significant bottleneck, introducing risks like overselling, stockouts, and inefficiently tied-up capital.

While automating is the logical next step, the complexity of finding the right solution, integrating software, and training your team can make any retailer hesitate.

However, with a methodical plan, the transition can be managed smoothly, unlocking new levels of operational efficiency.

In this article, we provide a step-by-step walkthrough to help you automate your ecommerce inventory management.

Linnworks demo: how to master inventory management

Master inventory management with Linnworks. Centralize stock and automate updates across all your sales channels effortlessly.

What is automated inventory management?

Automated inventory management refers to the use of technology and software to streamline and optimize inventory tracking and management processes.

Unlike traditional manual inventory methods that often rely on spreadsheets and physical counts, inventory management automation provides you with real-time updates, and comprehensive insights into stock levels, orders, and sales trends.

A 5-step framework for implementing your automated system

Adopting an automated inventory system without disrupting operations requires a clear, structured plan.

We’ve broken the process down into five key phases to ensure a smooth transition:

- Assess your current inventory management processes

- Choose the right automated inventory management software

- Integrate the system with existing infrastructure

- Train your team

- Monitor and optimize your system

Here’s a more detailed look at each:

Step 1: Assessing your current processes

Understanding your current state will help you determine what features and capabilities you need from an automated inventory management system. Inventory automation can’t solve what you haven’t diagnosed.

You’ll need to identify specific pain points, inefficiencies, and areas that need improvement. Questions to ask yourself include:

- How accurate are your inventory counts?

- Are you relying too heavily on manual processes?

- Are you experiencing frequent stockouts or overstock situations?

- Can you track inventory across multiple locations easily?

- Do you have a clear understanding of your best-selling and slow-moving items?

- How quickly can you fulfill orders?

- Are you able to keep a close eye on inventory levels?

Clear answers to these questions lay the foundation for successful automated inventory management.

Step 2: Choosing the right software

With your needs firmly established, dive into some research and pick the right software for your business. The precise features, scalability, and integration capabilities will vary depending on the size and type of your enterprise. However, as a general rule:

| Business size | Needs | Features to look out for |

| Small | Easy setup, minimal maintenance, affordable, non-technical team | User-friendly interface, centralized inventory tracking, basic order management, low-stock alerts |

| Medium | Scalability, system integration, data analysis, multiple sales channels | Multi-channel integration, multi-location support, advanced reporting, demand forecasting |

| Large | High-volume efficiency, customization, complex operations | Advanced warehouse management, custom workflows, role-based access control, sophisticated automation tools |

- Small businesses typically need a user-friendly, cost-effective system that’s easy to set up and maintain. Look for features like centralized inventory tracking, basic order management, and low-stock alerts that keep you in the loop without overwhelming you.

- Medium-sized enterprises need software that can handle larger volumes of data, integrate with other business systems, and create custom reports. Key features include multi-channel integration, multi-location support, advanced reporting and analytics, and accurate demand forecasting.

- Large ecommerce operators require even more sophisticated automation to handle the demands of high-volume processing. Additional features might include advanced warehouse management, customization options, and state-of-the-art collaboration and access control tools.

Step 3: Integrate with your existing infrastructure

Your ecommerce tech stack should never be a chaotic puzzle of disconnected tools. A connected order management system ensures your tools don’t operate in isolation.. The best systems make it straightforward to:

- Collate info from ecommerce platforms like Shopify, WooCommerce, Adobe Commerce, on one centralized dashboard.

- Connect payment processing solutions like PayPal, Stripe, Square, and Braintree.

- Integrate CRM tools like Salesforce, HubSpot, and Zoho.

- Sync with shipping and logistics providers like FedEx, UPS, and DHL.

- Link up your accounting software and customer service tools.

Step 4: Train your team

Even the most advanced ecommerce inventory management system won’t deliver results unless your team knows how to use it effectively. Training is where automation meets execution. Here’s how to ensure your team is ready to get the most out of your new system:

- Keep it practical: Run interactive sessions with real-life scenarios, not just theory. Let employees experience how the system works in day-to-day situations from receiving stock to fulfilling orders.

Develop clear, role-specific resources: Create user-friendly guides and quick-reference materials tailored to each role. For example, warehouse staff should focus on barcode scanning and stock handling, while sales teams may need to learn how to access inventory data and run basic reports. - Encourage ongoing feedback: Maintain open channels for your team to ask questions, share challenges, and suggest improvements. Their input will help refine future training and flag any system limitations early.

- Follow up and support: Training doesn’t end after one session. Offer follow-up support and refreshers to reinforce learning and help new hires get up to speed quickly.

Step 5: Monitor and optimize

After adopting an automated inventory management system, you’ll need to continue to monitor performance and make strategic adjustments. These include:

- Reviewing key metrics regularly: Keep an eye on inventory turnover, stock accuracy, fulfillment rates, and system performance. Spot inefficiencies early before they impact your bottom line. Smart inventory management lets you anticipate problems before they surface.

- Refining automation rules: Update reorder points, lead times, and stock thresholds as demand patterns shift. Review and optimize workflows to reflect current business needs.

- Optimizing demand forecasting: Use your system’s analytics to spot trends, adjust forecasts, and plan for seasonality or sales events.

- Auditing for errors: Periodically check for sync issues, data mismatches, or outdated integrations, especially if you’re selling across multiple platforms.

- Listen to your team: Frontline users often notice issues before they show up in reports. Encourage feedback and keep lines of communication open. Inventory automation only works if the system evolves with your business.

Benefits of automating inventory management

Implementing automated inventory management may seem like a daunting undertaking but once a system is in place, the benefits are clear. Inventory automation simplifies what once felt impossible.

Here’s a breakdown of how the right system helps you reduce stress, save time, cut costs, and even deliver a better customer experience:

Improved Accuracy

When done manually, ecommerce inventory management is vulnerable to human error. A decimal point out of place could lead to devastating stock discrepancies that affect the entire operation. Such errors can mean inaccurate stock levels, delayed shipments, or even lost customers. Automation eliminates this risk by updating stock levels in real time across channels and warehouse locations. This ensures that what you see in the system truly reflects what’s on the shelves, giving you the confidence to make accurate decisions about restocking, fulfillment, and promotions.

Cost Savings

An automated inventory management system most obviously means a reduction in labor costs. Automated systems handle the repetitive tasks that drain resources over time. It minimizes the need for manual stock counts, data entry, and error correction among other operational tasks.

But more than this, automating inventory management also helps gives you real-time updates on inventory levels which prevents overstocking, meaning less capital spent on unsold goods, warehousing costs, and inventory write-downs. At the same time, it protects against understocking which leads to lost sales, backorders, and customer dissatisfaction.

Enhanced Operational Efficiency

Automation transforms inventory handling from a reactive, manual process into a streamlined, proactive system. Warehouse teams gain real-time visibility into stock locations, enabling faster order picking, packing, and shipping with minimal error. This efficiency allows fulfillment operations to scale without too large an increase in headcount or complexity. Reduced lead times, fewer mispicks, and faster order processing all contribute to improved customer satisfaction and retention.

Scalability

Growth often exposes the limitations of manual systems. As product lines expand, order volumes increase, and new sales channels are added, keeping operations in sync becomes more challenging. Automated inventory systems are built to solve this complexity. They centralize control across multiple warehouses, sales platforms, and supplier relationships—allowing businesses to become more agile.

Smarter Decision-Making

Modern systems leverage historical sales data, seasonal trends, and real-time stock insights to support intelligent forecasting and demand planning. This results in more accurate reorder points, optimized stock levels, and fewer emergency restocks or excess inventory write-offs. Automated dashboards and alerts give stakeholders visibility into inventory performance at a glance, empowering cross-functional teams to make faster, more aligned decisions.

Improved Customer Service

Automated inventory management systems give customer-facing teams the information they need instantly. Real-time stock visibility enables accurate delivery estimates, proactive communication about delays, and faster resolution of order issues. With fewer stockouts and mispicks, customers will consistently receive the right product, on time. This reliability builds trust, reduces returns, increases repeat purchases, and ultimately long-term customer loyalty.

Regulatory Compliance

Automated inventory management systems help maintain compliance by providing accurate, time-stamped records of inventory movements, batch numbers, expiry dates, and supplier details. This level of traceability not only supports internal audits but also ensures you’re prepared for external inspections and reporting requirements. With built-in safeguards and real-time reporting, an automated inventory management system helps businesses avoid costly penalties, ensuring that compliance doesn’t end up becoming a bottleneck.

What to look for in an automated inventory management solution

A strong automated inventory management solution should provide:

- Real-time inventory tracking

- Multi-channel integration

- Automated reorder points and stock alerts

- Demand forecasting and analytics

- Barcode and RFID integration.

These features work together to reduce manual effort, eliminate costly errors, and give you the visibility needed to scale confidently. Here’s why each matters:

Real-time inventory tracking

Effective inventory management relies on visibility that’s both real-time and reliable. Real-time tracking capabilities give you instant visibility on your inventory levels across all warehouse locations, helping you avoid stockouts and allowing you to respond quickly to changes in demand.

Real-time data like this empowers your warehouse team to pick and pack faster, helps operations adjust reorders instantly, and allows more accurate cash flow projection.

It also ensures that you’re able to immediately adapt during high-demand periods—like holiday sales or flash promos— without overselling or missing out.

Multi-channel integration

The best automated inventory management solutions can integrate seamlessly with several global marketplaces, D2C platforms, shipping providers, and 3PLs. Centralized control ensures stock levels are updated in real-time and that sales and delivery processes run smoothly no matter where your customers shop.

Platforms like Amazon, Shopify, eBay, and Walmart Marketplace are often part of the integration mix, giving you full visibility from a single dashboard. This eliminates painful issues like overselling on one channel while sitting on excess inventory elsewhere.

If a product sells out on Shopee, your system can automatically update your Shopify and TikTok shop to prevent backorders.

Need help upping your multi-channel selling strategy? Here’s some top tips from Darin Lynch, CEO and founder of Irish Titan ecommerce agency.

Automated reorder points and stock alerts

When you automate inventory management, you’re able to set reorder points based on historical sales data to alert you when it’s time to restock. The most efficient automated inventory management systems even generate purchase orders for you, eliminating more operational tasks while simultaneously minimizing the risk of stockouts and avoiding costly last-minute supplier orders.

These reorder points can factor in lead time, safety stock buffers, and demand variability, ensuring your replenishment cycle is always ahead.

Automated reorder points and stock alerts also foster better supplier coordination by giving partners advance notice and reducing delivery friction.

Demand forecasting and analytics

Automated inventory management software should provide powerful analytics based on sales trends, evolving consumer preferences, and current market conditions. With accurate stock forecasting, you’ll be able to reduce dead stock and carrying costs while ensuring warehouse space remains abundant.

Key metrics like sell-through rate, inventory turnover ratio, and days of stock on hand help you refine decisions. Planning for peak seasons, for example, becomes far less guesswork and more strategy as you’ll know when to scale up and when to hold back.

Barcode and RFID integration

Adding barcode and RFID technology to your automated inventory management system makes intake fast and foolproof. You’ll speed up tracking, cut down on errors, and always know exactly what’s in stock.

Barcodes work well for item-level scanning, while RFID allows for bulk reads without direct line of sight, making it ideal for fast-moving or high-volume warehouses.

Top Automated Inventory Management Solutions

Understanding which features you need to look out for is only half the story. Choosing the right automated inventory management solution also involves finding one that fits your operations. It would be a misalignment to adopt a solution meant for an enterprise if your business is still growing and doesn’t have the infrastructure, budget, or complexity to support it. Here’s a side-by-side look at five major players in the space so you can find the best fit for your needs.

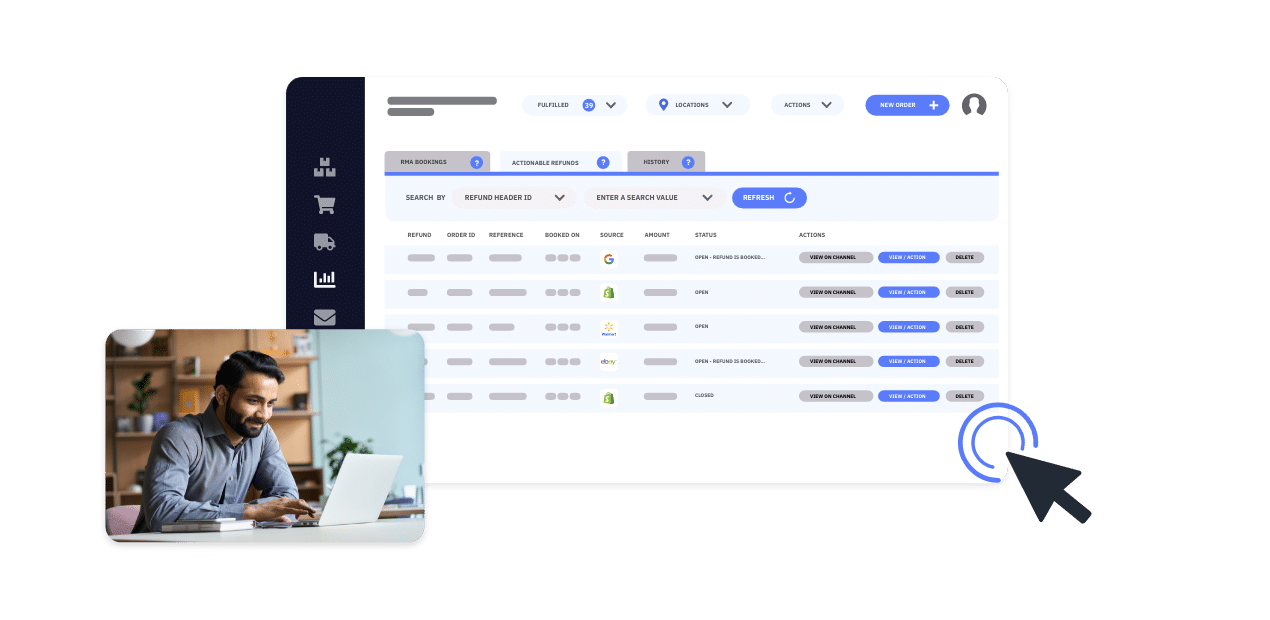

1. Linnworks

Best for: Ecommerce businesses that need end-to-end visibility and control across multiple sales channels without the complexity of enterprise software.

Best for: Ecommerce businesses that need end-to-end visibility and control across multiple sales channels without the complexity of enterprise software.

Key Features:

Key Features:

- Real-time inventory tracking across all selling channels

- Deep multi-channel integration (Amazon, eBay, Walmart, Shopify, BigCommerce, and more)

- Automated reorder points and low-stock alerts

- Demand forecasting and advanced analytics

- Barcode scanning (RFID support via third-party integrations)

- Centralized order, listing, and shipping management

See Linnworks in action

find out how inventory management can help you streamline your ecommerce operation and grow your business.

2. Cin7

Best for: Businesses selling across retail, wholesale, and online channels that need built-in POS and B2B tools.

Key Features:

Key Features:

- Inventory and order management with POS and B2B portal

- Real-time stock tracking

- Multi-channel integration

- Barcode and RFID support

- Demand forecasting and automation

- Built-in EDI for major retailers

Drawbacks:

Drawbacks:

- Steeper learning curve

- Higher setup and support costs

- May require additional modules for full ecommerce capabilities

3. Unleashed Software

Best for: Small to mid‑sized ecommerce, distribution, and light manufacturing businesses that need robust warehouse inventory control, automated replenishment, and accounting integrations.

Key Features:

Key Features:

- Real-time inventory tracking, including batch and serial number tracking

- Connects with Shopify, Amazon, WooCommerce, eBay, and B2B platforms

- Automated reorder points and low-stock alerts

- Basic demand forecasting and business reporting dashboards

- Barcode scanning and optional RFID support

- Integrates with Xero, QuickBooks, and Salesforce

Drawbacks:

Drawbacks:

- Doesn’t handle listings, order routing, or shipping like Linnworks

- Forecasting is basic compared to more advanced tools

- RFID setup may need extra hardware or third-party apps

- Scaling across many sales channels may require added software

4. Zoho Inventory

Best for: Small businesses and startups looking for an affordable entry point into automated inventory management.

Key Features:

Key Features:

- Real-time inventory updates

- Basic multi-channel integration (Shopify, Amazon, eBay, Etsy)

- Stock alerts and reorder rules

- Integration with Zoho ecosystem (CRM, Books, etc.)

Drawbacks:

Drawbacks:

- No native RFID support

- Limited forecasting and analytics

- Not ideal for scaling across multiple warehouses or high-SKU businesses

5. NetSuite (Oracle)

Best for: Large enterprises already using or planning to implement NetSuite as their ERP backbone.

Key Features:

Key Features:

- Real-time inventory and supply chain visibility

- Forecasting and financial analytics

- Multi-channel integration via connectors

- Automated purchasing, billing, and warehouse tracking

- Barcode/RFID support with custom implementation

Drawbacks:

Drawbacks:

- Expensive and complex to implement

- Overkill for small and mid-sized ecommerce brands

- Requires developer support for customization and integration

Why Linnworks stands out

As an automated inventory management solution, Linnworks offers the best balance of power, usability, and scalability for growing ecommerce brands. Unlike enterprise-grade tools that can overwhelm smaller teams, Linnworks delivers advanced features like deep multi-channel integration, centralized order control, automated stock replenishment, and real-time performance analytics, all without requiring complex infrastructure or developer support.

Its end-to-end visibility, real-time automation, and native integrations with major marketplaces make it a reliable hub for managing inventory, listings, and fulfillment in one place. Whether you’re streamlining existing workflows or preparing to scale, Linnworks is built to grow with you.

Ready to take control of your inventory operations? Book a demo and see how Linnworks fits your business.

The post Implementing an automated inventory management system: A step-by-step guide appeared first on Linnworks.