In today’s global marketplace, brands have more choices than ever when sourcing flexible packaging. While the allure of lower costs from overseas suppliers can be tempting, it’s crucial to look beyond the price tag and consider a factor that directly impacts consumer safety and brand reputation: the inks used in the printing process.It’s not just UV inks that raise concerns. UV coatings, which cure the same way, can also harbor photoinitiators and unreacted monomers capable of migrating into food.

At ePac Flexible Packaging, we champion domestic production not just for speed and flexibility, but critically, for the enhanced quality control and adherence to stringent safety standards it allows. A significant point of difference we often see compared to packaging and labels sourced from some overseas suppliers is the prevalent use of Ultraviolet (UV) curable inks, especially in applications where they may pose risks.

Understanding UV Inks and the Potential Risks

UV inks are popular in many printing sectors because they cure almost instantly when exposed to UV light. Similarly, UV coatings, which apply a protective varnish over printed areas, use the same photoinitiator chemistry and carry identical migration hazards if not fully cured.This rapid drying allows for faster production speeds and can produce vibrant, high-gloss finishes. However, when it comes to packaging for food, beverages, pharmaceuticals, supplements, pet food, and other consumable products, standard UV inks harbor a hidden danger: migration.

The curing process for UV inks relies on components called photoinitiators. If the ink isn’t fully cured (which can happen due to various factors like ink thickness, cure lamp intensity, or line speed), these photoinitiators and other unreacted substances can remain mobile within the ink layer. Over time, especially when in direct contact with or close proximity to the packaged product, these substances can migrate through the packaging film layers and potentially transfer into the product itself.

Why is Ink Migration a Concern for Consumables?

Food Safety

Photoinitiators and other UV ink and coating components are not intended for human consumption. While the exact long-term health effects of ingesting low levels of these chemicals are still being studied, regulatory bodies like the U.S. Food and Drug Administration (FDA) have strict regulations concerning substances that can migrate into food. Packaging sourced from overseas suppliers operating under different regulatory structures may not always adhere to the same rigorous testing and compliance standards required domestically, increasing the risk of non-compliant inks and coatings being used for food applications.

Taste and Odor

Ink component migration can also affect the sensory properties of the product, leading to off-tastes or undesirable odors, ultimately damaging the consumer experience and brand perception.

Broader Consumables

The risk isn’t limited to food. Products like dietary supplements, cosmetics (lip balms, lotions), and pet foods can also be contaminated through migration, potentially exposing consumers or their pets to unintended chemicals.

Understanding Sourcing Dynamics and Ink Choices

Why might standard UV inks be used more readily by some overseas suppliers, even for sensitive applications? Often, this tendency can stem from intense cost pressures in highly competitive global markets. Standard UV inks can be less expensive than specialized low-migration or food-compliant ink systems. Furthermore, different regulatory requirements and levels of enforcement regarding food contact materials in certain manufacturing regions can mean that practices acceptable locally may not meet the stricter standards required in markets like the U.S. or E.U. This isn’t universally true, but it represents a potential risk factor when sourcing packaging primarily based on the lowest cost from overseas.

The ePac Difference: Domestic Production & Safer Ink Systems

This is where choosing a domestic packaging partner like ePac provides a distinct advantage.

Food-Compliant Inks

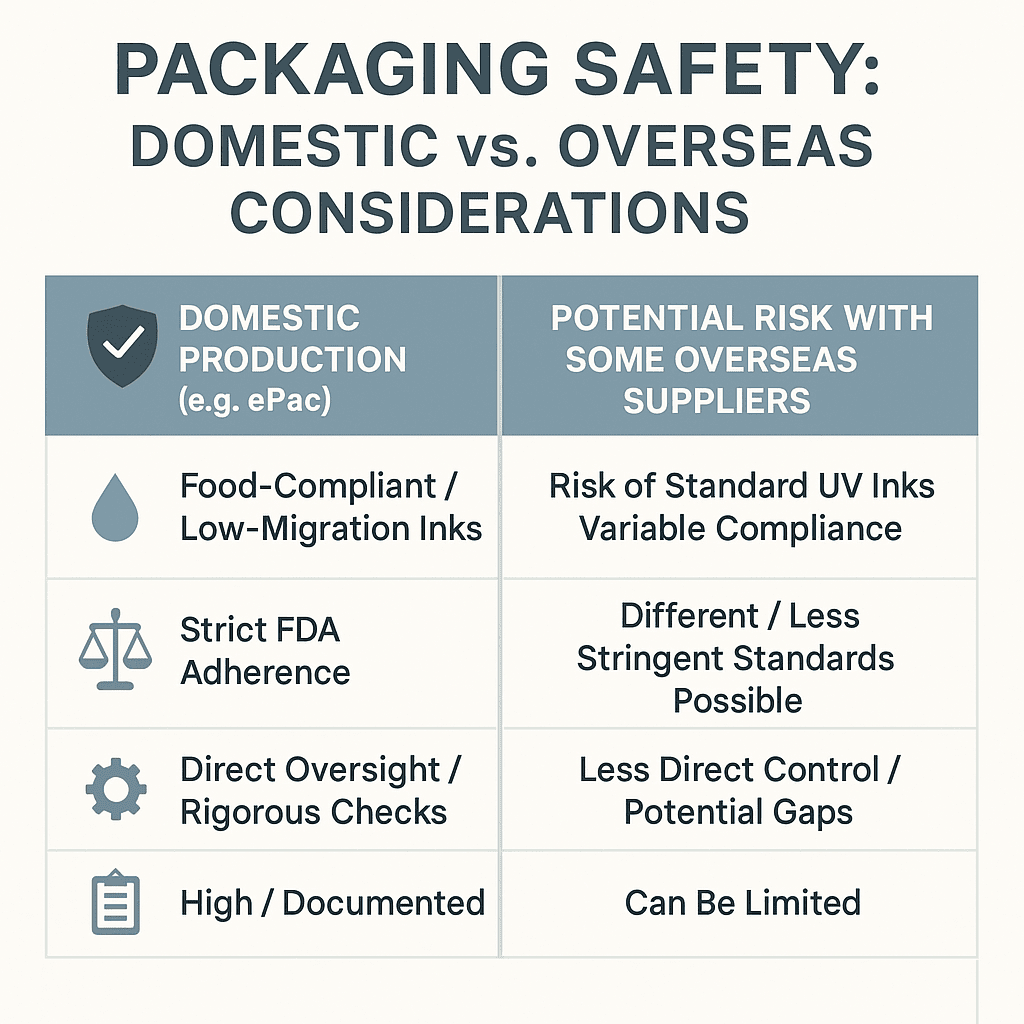

ePac utilizes state-of-the-art digital printing technology with inks specifically designed and certified for compliance with food safety regulations. These are often low-migration ink systems formulated to minimize the risk of component transfer, ensuring that your packaging meets FDA and other relevant standards for indirect food contact.

Rigorous Process Control

Our domestic production facilities operate under stringent quality control protocols. We have direct oversight of the entire process, from material selection to printing and finishing, ensuring that inks are applied and cured correctly according to validated procedures.

Regulatory Adherence

Operating within the United States means we are directly subject to FDA regulations and guidelines for food contact materials. We prioritize compliance, providing peace of mind that your packaging is safe for its intended use, a guarantee harder to ensure with distant overseas suppliers.

Transparency & Trust

Partnering with a domestic supplier like ePac offers greater transparency into the materials and processes used. We can readily provide documentation and assurance regarding the safety and compliance of our packaging.

The Added Benefits of Domestic Partnership

Don’t Compromise on Safety

Choosing ePac also brings advantages like faster turnaround times, lower minimum order quantities, supply chain reliability, and the ability to rapidly iterate on designs – benefits made possible by our network of local US facilities and our digital printing platform.

While imported packaging might seem economically advantageous initially, the potential risks associated with non-compliant materials sometimes found when sourcing packaging overseas, particularly the use of standard UV inks and coatings for consumable products, can have serious consequences for consumer health and brand integrity.

At ePac Flexible Packaging, we believe safety is non-negotiable. By prioritizing domestic production using food-compliant ink systems and rigorous quality control, we provide brands with packaging that is not only vibrant and high-quality but also safe, compliant, and trustworthy. Protect your customers and your reputation by making the informed choice for your packaging partner.

This article was written with the help of artificial intelligence.